Unnecessary Inventions’ Tiny Marvel is Literally a 3D Printer That Prints Itself

Matty Benedetto of Unnecessary Inventions has a habit of turning fleeting ideas into tangible realities. His latest project, a 3D-printed 3D printer, is proof of that. Built from a Japanese open-source design called the Fraxinus 00TW, this tiny printer is a mix of ambition, creativity and just enough chaos to keep things interesting.

Inspiration can strike from anywhere and for Benedetto it came from a single image of a tiny 3D printer on Twitter. The photo, in Japanese, was of the Fraxinus 00TW, a design by Summer Orange. His first step was to find the source. After translating the tweet and navigating a Japanese website he found the Discord community where Summer Orange shared the project. Becoming a beta tester gave him access to a Google Drive full of CAD files, a bill of materials and a detailed instruction manual – mostly in English, to his relief.

Sale

Creality K1 SE 3D Printer, 2024 New Version 600mm/s High-Speed Hands-Free Auto Leveling Flagship-Level…

- 【12X Speedy with CoreXY】K1 SE 3D Printer inherits the lightweight and agile CoreXY system of the K1 series. Max 600mm/s speed and 20000mm/s²…

- 【Flagship Reliable Extruder】Crealitry k1 se uses the same extruder as k1c. The extruder equipped with a newly added side spring & ball plunger,…

- 【Durable Tri-metal Nozzle & 60W Hotend】Easy to maintain & quick to swap. The durable steel-tipped copper nozzle is integrated with a titanium…

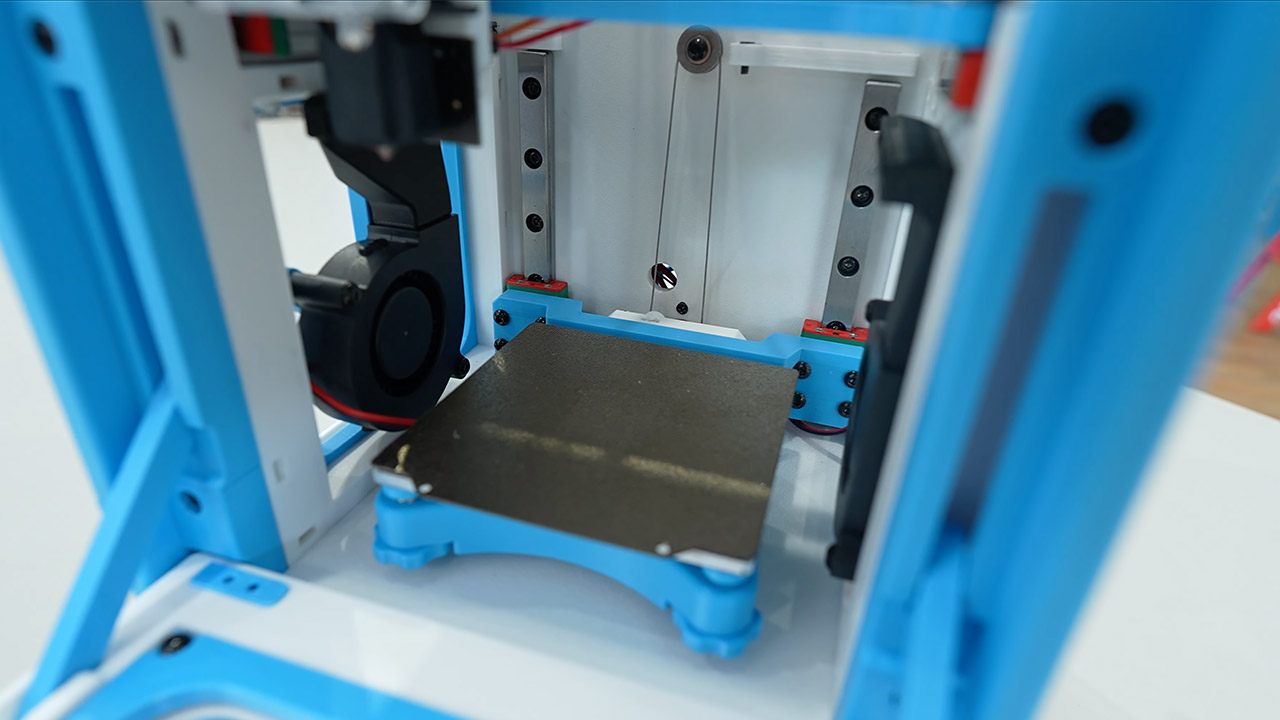

He’s no stranger to 3D printing, but Matty is used to plugging in ready-made machines, not building them from scratch. The project required a mix of 3D printed parts and sourced components, many of which were listed in Japanese with links to US retailers that didn’t exist. Over a week he translated part names, hunted for equivalents and ordered them online. As packages arrived his studio was filled with a jumble of motors, wires and a custom made 70x70mm build plate – small enough to make a standard printer’s plate look like a giant. To keep things organized he leaned on his 3D printing skills and printed the printer’s parts in his signature teal blue and white ABS filament across his print farm.

Benedetto printed out a 60 page instruction manual, a habit he has of keeping paper boarding passes for flights. The frame came together first, with grooves and notches so parts would fit together before screws would secure them. An electric screwdriver from Hoto made quick work of the repetitive tasks, a tool he hadn’t used in a project before. The drive system, a complex core XY setup using metal wire instead of belts due to the printer’s small size, was a test of his patience. Each step required precision or he’d make a costly mistake and have to start over. When he got confused he cross referenced the 3D model on his computer to make sure every part fit. The Discord community was his lifeline, where he posted progress photos and waited for feedback, hoping he hadn’t messed up the build.

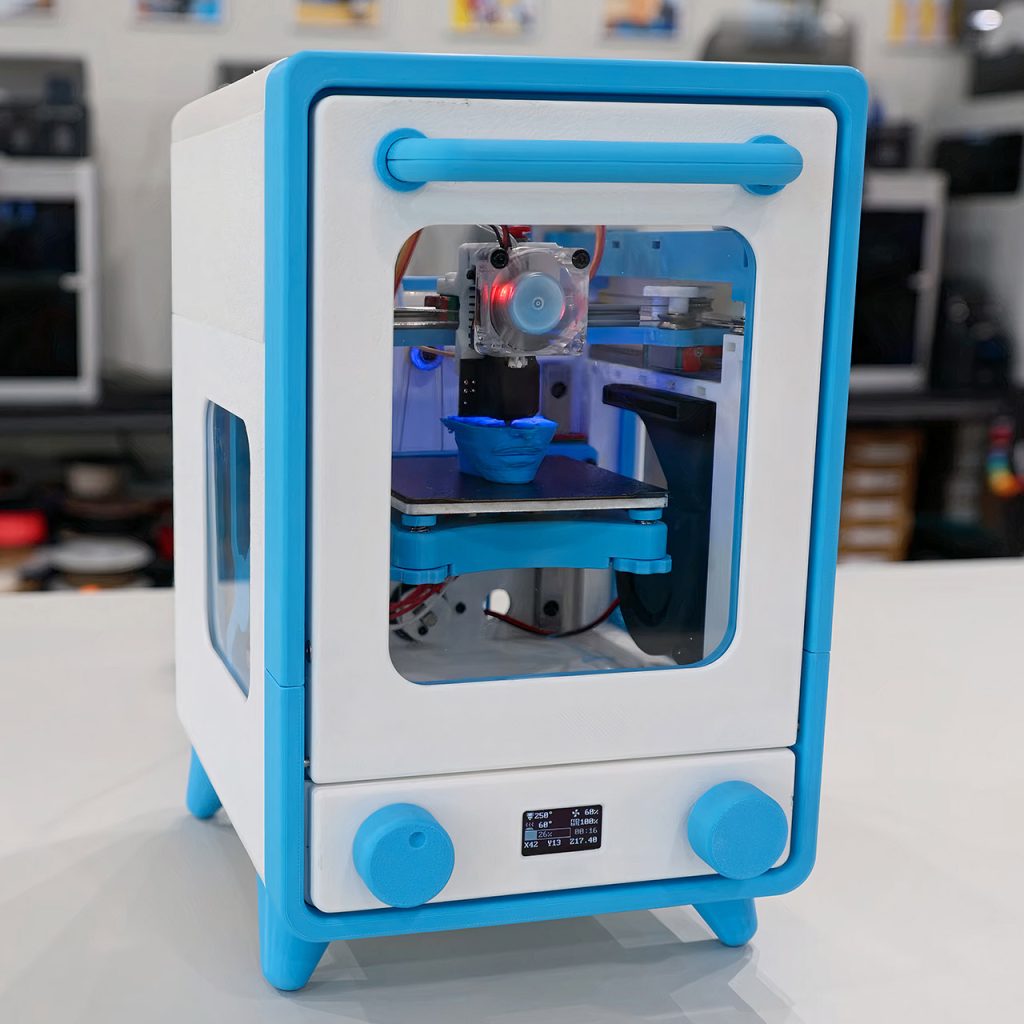

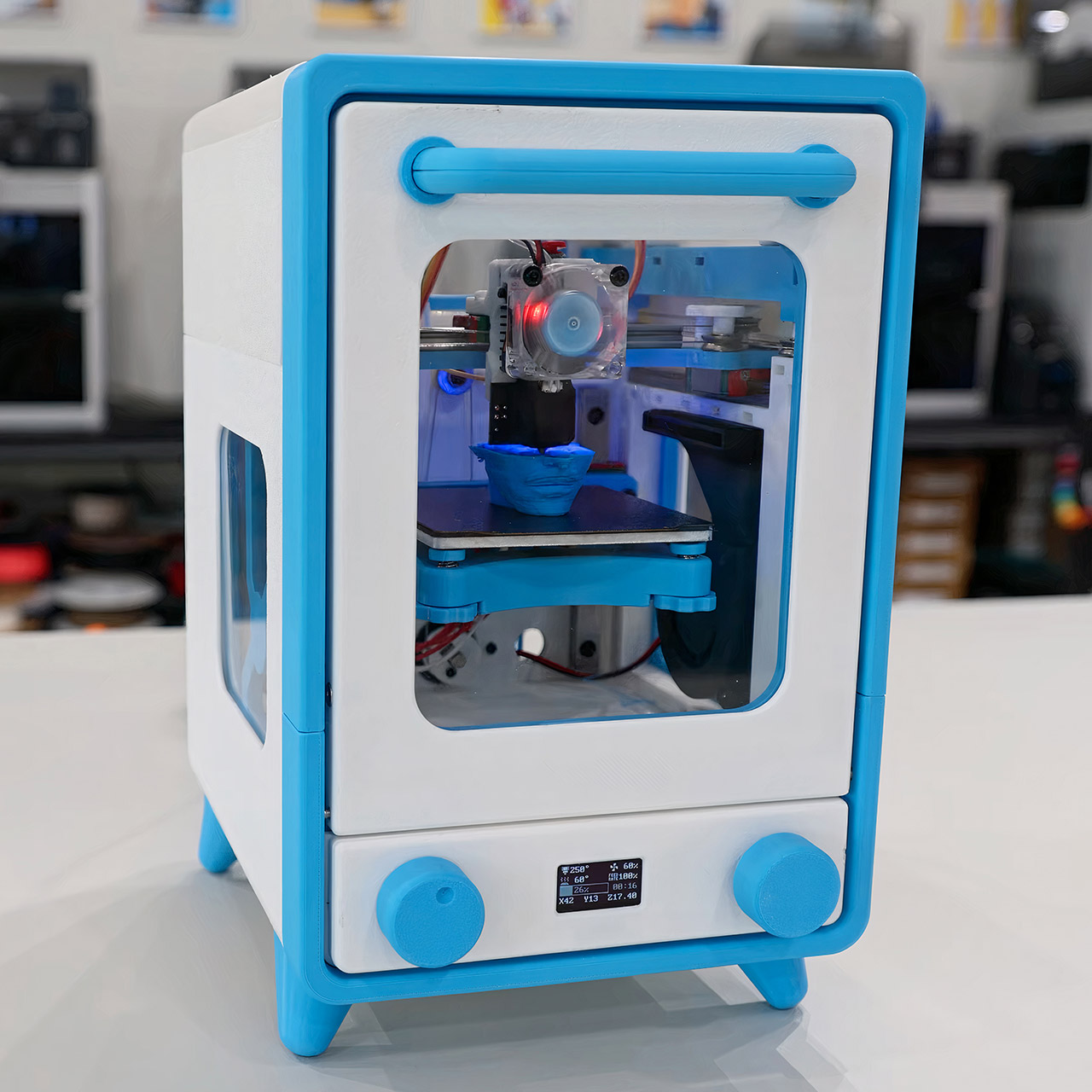

After days of building, the moment of truth arrived: a test print. Powered by a portable power bank, the Fraxinus 00TW sprang to life, its extruder humming as PLA filament fed through a Bowden tube. The tiny build plate leveled and the printer started laying down its first layers. It wasn’t perfect – there was some banding and the top layer was rough – but it worked. Benedetto’s creation, a 3D printer born from another 3D printer, was a success. The final touches included a magnetic door that snaps shut like a tiny oven and a small LCD screen displaying print stats. Completely cordless, the printer can run anywhere, Benedetto plans to use this to his advantage by designing a shoulder strap for on-the-go printing.

Unnecessary Inventions’ Tiny Marvel is Literally a 3D Printer That Prints Itself

#Unnecessary #Inventions #Tiny #Marvel #Literally #Printer #Prints