Tech Enthusiast Provides a Rare Look Inside an iPhone Screen Factory

Scotty Allen from Strange Parts goes into a Shenzhen factory to see how the glass screens on millions of iPhones are made. His tour was shot entirely on an Insta360 X5 and pulls back the curtain on a process rarely seen by the public. With his friend Hang, a seasoned player in the aftermarket iPhone component trade, Allen visits clean rooms and machinery to show the step by step process of how the glass and touchscreen layers are made that define the iPhone experience.

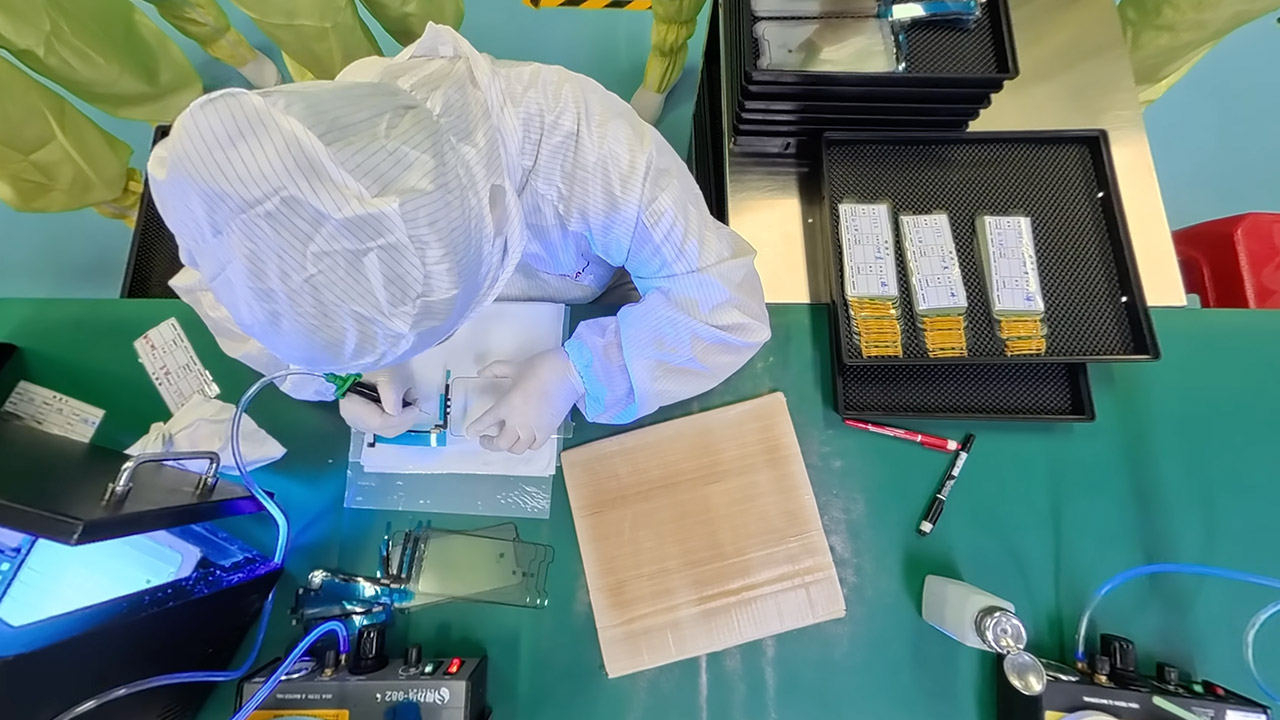

Clean rooms rule the factory, where dust is the enemy. Workers wear full-body suits, booties and hairnets to make sure no outside particles get in the glass. Allen and Hang are dressed accordingly and head to a area where iPhone screen glass begins its journey. Large slabs of glass, enough for several screens, arrive at the site. Machines cut these sheets into smaller rectangles, each will be the front glass of an iPhone. A worker feeds 4 parts at a time into a cutting machine which cuts the rounded corners.

Insta360 X5 – Waterproof 8K 360° Action Camera, Leading Low Light, Invisible Selfie Stick Effect, Rugged…

- 8K30fps 360° Video with Dual 1/1.28″ Sensors: Capture stunning detail with dual 1/1.28″ sensors shooting up to 8K30fps. Film epic adventures,…

- Triple AI Chip Design, Better Low Light: Shoot confidently even in challenging lighting. X5’s triple AI chip design powers advanced noise reduction…

- Invisible Selfie Stick: Create impossible third-person views with no selfie stick in sight! Capture everything in 360°, then choose your angles later…

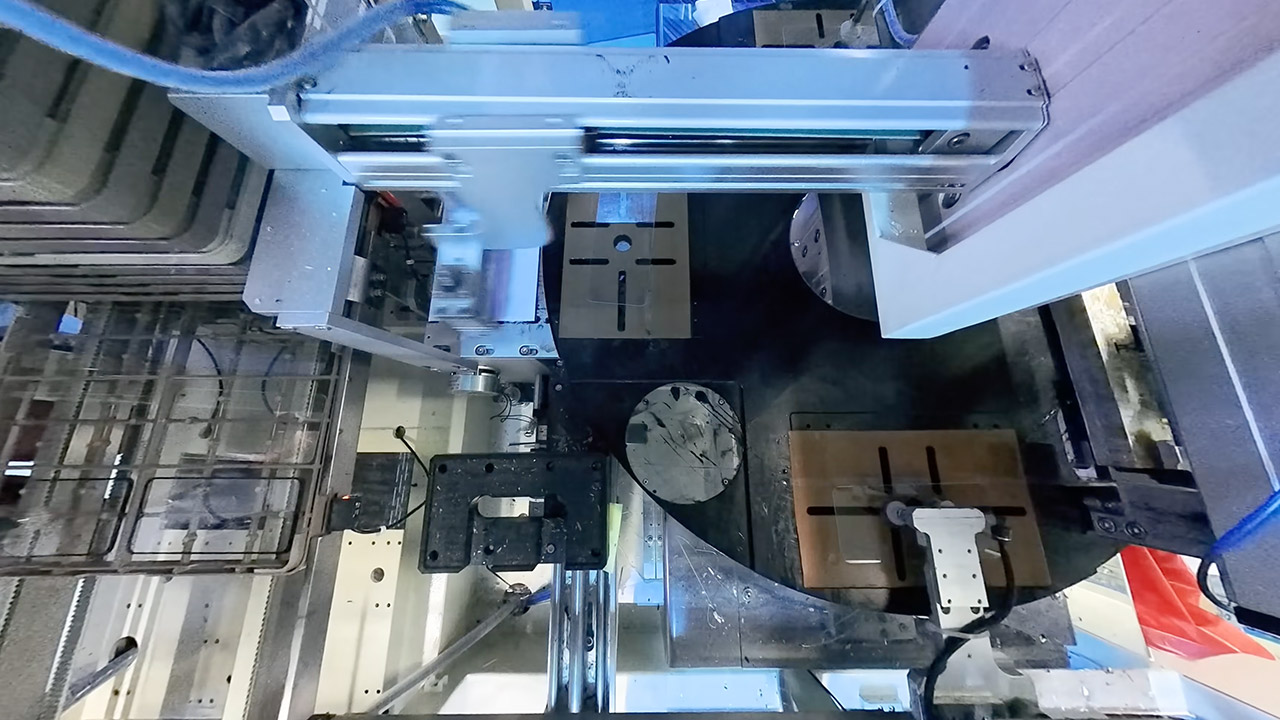

Next, they polish the rough edges into smooth curvy surfaces that feel premium in your hand. Allen is impressed by a machine that polishes many glass pieces at the same time, using a white racing compound to smooth the edges. The scale is staggering, as stacks of glass 10 pieces high move along the line. A high concentration detergent bath is then heated to 400 degrees Fahrenheit for 4 hours before slowly cooling to prevent cracking. This step ensures the glass is perfect before moving on to the next process. Allen points out the volume, one machine processes 4,000 parts at a time, showing how efficient the factory is.

The glass is silk-screened to add visual elements like logos or alignment markers. Workers apply black and white coatings to the glass, bake them in ovens to make them durable. An oleophobic coating, same as what Apple uses to repel fingerprints, is sprayed on the glass, making it feel sleek. Each piece is then sealed in plastic to protect it from dust, an important step before shipping. Allen notes the economics: this glass which is often the only part that gets destroyed when a screen cracks costs 50 cents. But replacing an iPhone screen at a Western repair shop can cost hundreds, so understanding the supply chain is key.

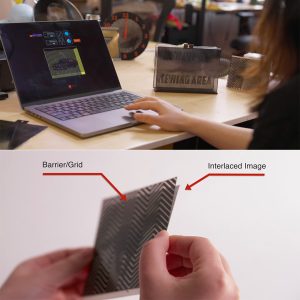

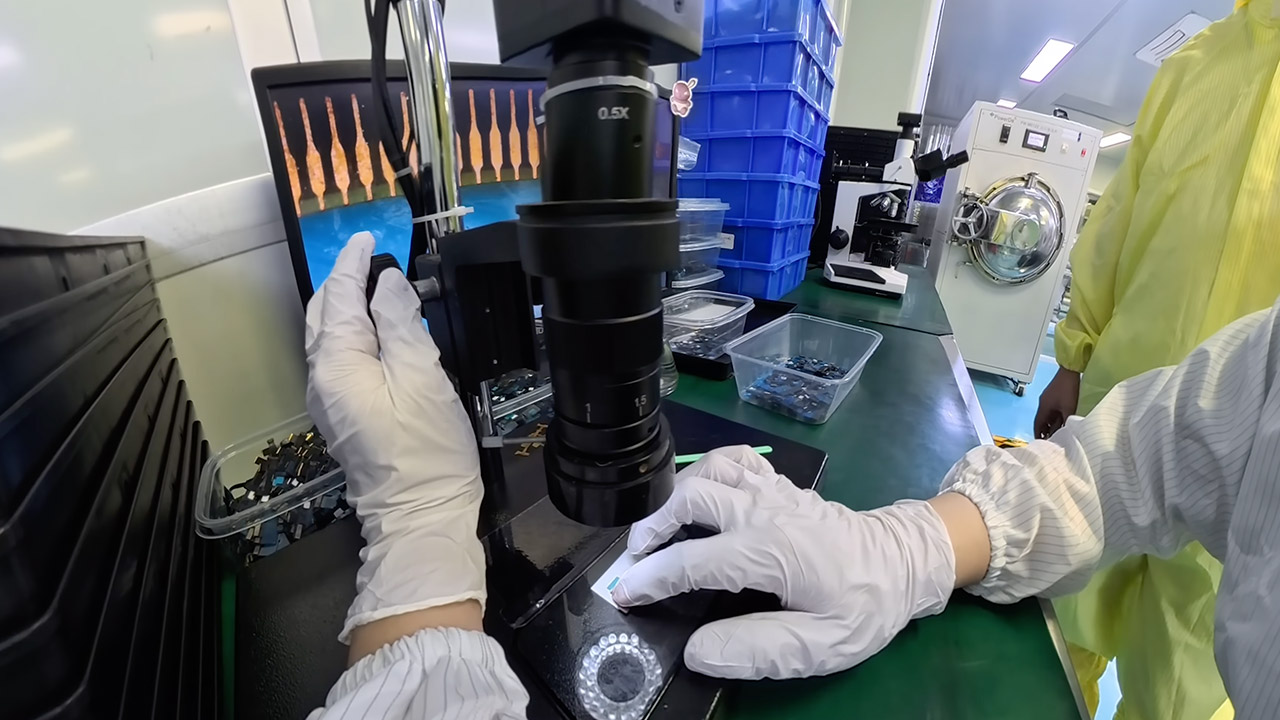

Allen and Hang head into the touchscreen factory, into another clean room. This time. they’re focusing on the touch-sensitive layer beneath the glass. The process starts with quality tests on flex cables, the delicate connectors that connect the touchscreen to the phone’s internals. To connect the flex cable to the touchscreen, a special adhesive called ACF (anisotropic conductive film) is used. This glue carries electricity in only one direction: up. It’s perfect for connections without short-circuiting. Machines position the cables precisely and secure them with heat and pressure. Allen references a linked video that explains how ACF works, which uses microscopic metal balls in the glue to provide vertical conductivity without horizontal interference.

The touchscreen assembly continues with the application of adhesive, which is cured under UV light to attach components. Workers test the touchscreens on jigs that look like real iPhones, making sure they’re responsive, especially at the corners where problems often occur. Every piece is inspected and this room produces 150,000 units a month. The next step is to attach the protective glass to the touchscreen, which is done in a dust-free environment. Ionizing blowers and moisture control ensure a spotless room. Before the screens are packaged and ready for the aftermarket, a laser imprints the batch numbers on the frame in a quick and precise manner.

Tech Enthusiast Provides a Rare Look Inside an iPhone Screen Factory

#Tech #Enthusiast #Rare #iPhone #Screen #Factory