Boston Dynamics’ Spot Transforms Steel Maker POSCO’s Furnace Inspections

At POSCO’s Gwangyang Steelworks facility in South Korea, where molten iron blazes at over 1200°C, a feisty four-legged robot named Spot is making its way through the heat like a old friend. With 23 million tons of steel produced for 70 countries, this is the largest of its sort in the world.

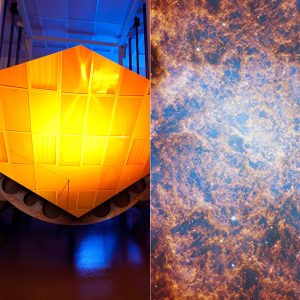

Essential to this process are blast furnaces, which transform raw materials into molten iron, which is used to create anything from skyscraper supports to automobile parts. One mistake and the whole business shuts down. Workers used to wear heavy gear to inspect for cracks or leaks, and go into the furnace multiple times a day. Spot’s arrival changed everything.

LEGO Super Mario: Mario Kart – Mario & Standard Kart Building Set for Adults – DIY Book Shelf & Room…

- HERE WE GO! – Speed down Rainbow Road with the LEGO Super Mario: Mario Kart – Mario & Standard Kart (72037) collectible building set for adults 18…

- DYNAMIC DISPLAY STAND – Position Mario at dramatic racing angles to recreate that perfect drift moment or high-speed action from your favorite Mario…

- POSEABLE MARIO FIGURE – The brick-built Mario features movable head and arms, letting you customize his racing pose for the ultimate display

Since 2023, Spot’s been the furnace’s full-time guardian, scurrying through the heat with a thermal camera that catches gas leaks, water drips or overheating at the furnace’s 44 critical tuyeres—the air-blast points that keep the fire burning. No bulky suits for Spot; it zips in and out, stays cool and delivers clear data. The workers? They’re loving it, now doing safer jobs, their days a little brighter knowing Spot’s got the tough stuff covered.

Spot moves faster than fixed sensors can. The furnace is too complicated to cover from wall to wall because of its many pipes and components. But Spot roams like it owns the place, snapping thermal images that human eyes might miss.

Orbit, Boston Dynamics’ fleet management system, is Spot’s brain. POSCO’s team set up two daily “Autowalks,” each with 40 tasks, all managed through a dashboard that schedules missions and crunches data. Spot sends back live thermal readings, stores patterns to make better calls. They’re even going to hook Orbit into POSCO’s main systems, have Spot’s work sync with the plant’s rhythm like a beat.

POSCO’s looking to give Spot more work in the plant’s most challenging areas. They’re a “lighthouse factory” according to the World Economic Forum in 2019, and Spot’s the proof.

Boston Dynamics’ Spot Transforms Steel Maker POSCO’s Furnace Inspections

#Boston #Dynamics #Spot #Transforms #Steel #Maker #POSCOs #Furnace #Inspections