Inventor Shane Wighton’s Egg-Cracking Machine Cracks the Code

Inventor Shane Wighton, the genius behind the YouTube series Stuff Made Here, is known for turning everyday problems into engineering triumphs. His latest invention, a mechanical egg-cracking machine, tackles the messy, finger-sticky task of cracking eggs with ingenuity and persistence.

Wighton’s motivation was a decade long annoyance: cracking eggs left residue on his hands and he had to go to the sink every time. He wanted to find a solution so he imagined a handheld, purely mechanical device that could score, crack and eject an egg without electronics or heavy machinery. His idea was based on a simple principle from glasswork: score a line on an eggshell to weaken it then tap it to make a clean break. Sounds simple right? As Wighton found out, it’s not that simple, it was a journey of prototypes, broken eggs and a machine that’s as cool as it is crazy.

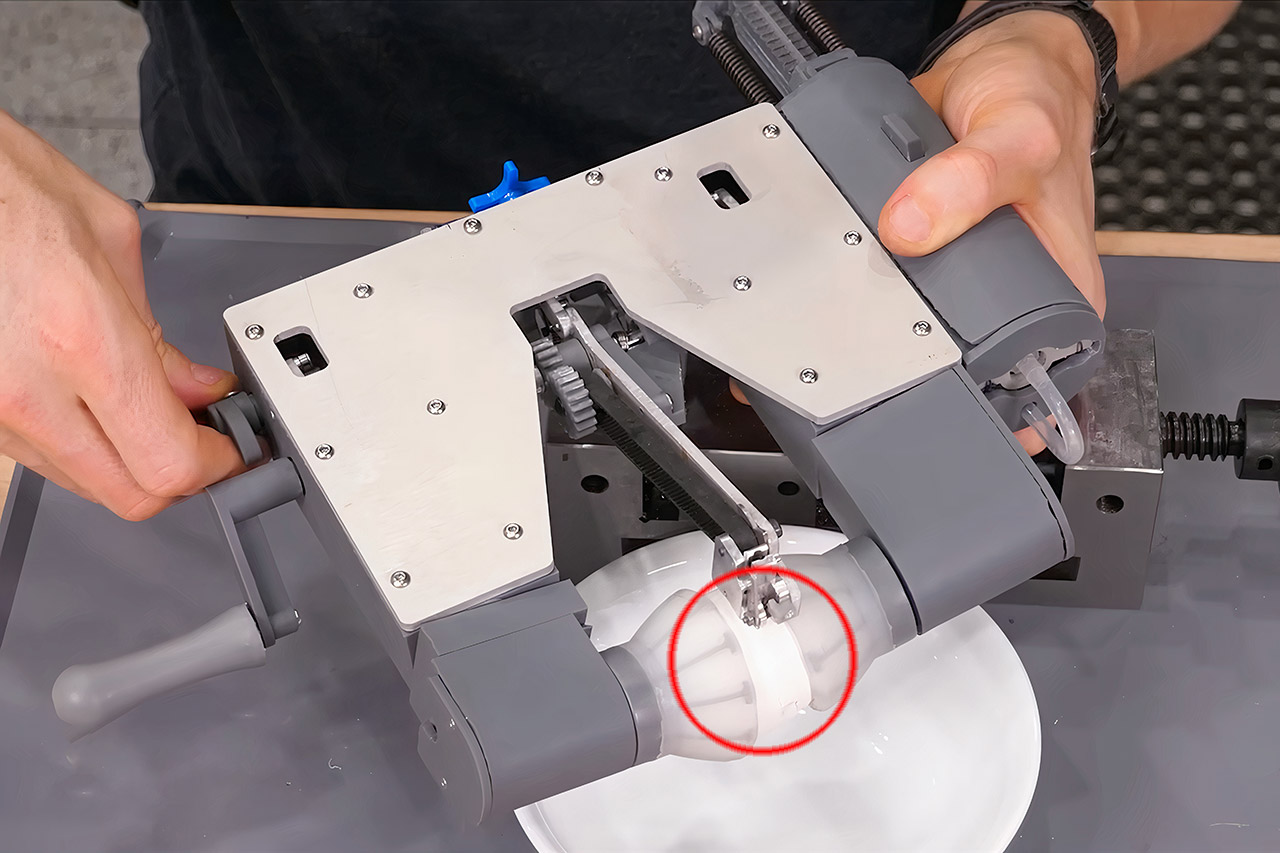

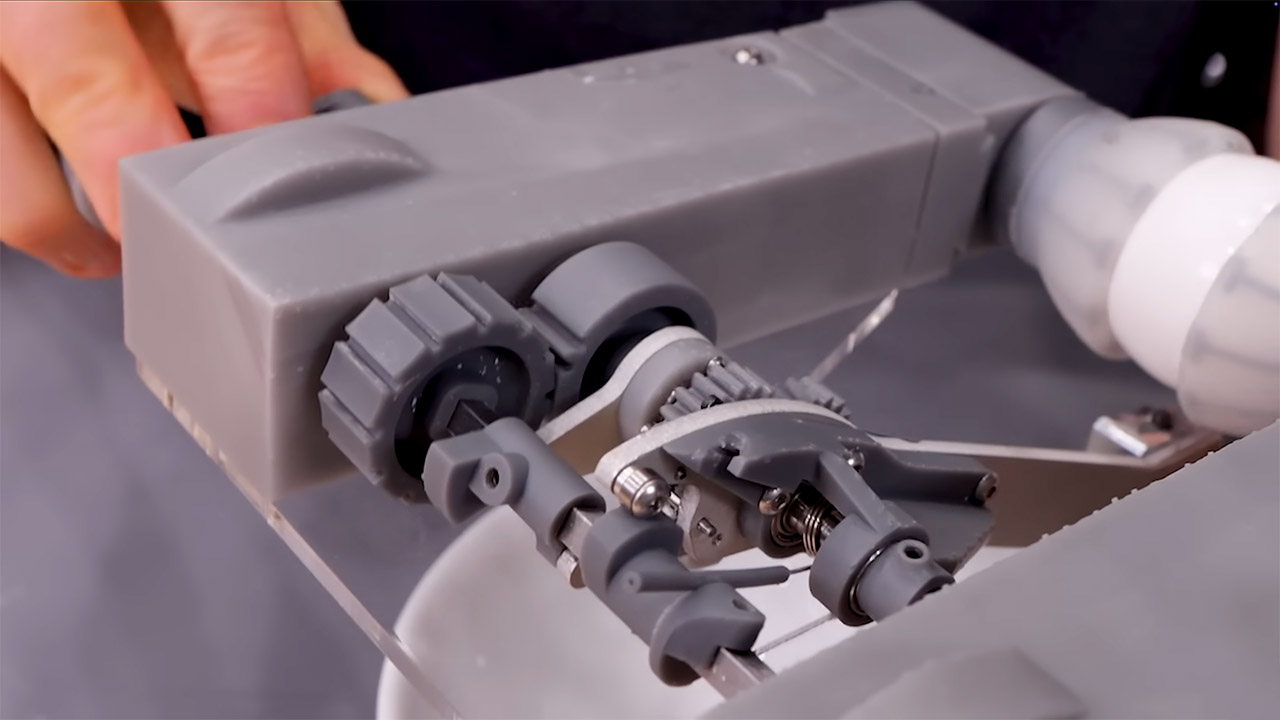

Holding an egg was the first big challenge. Eggs come in all shapes and sizes and their slick, curved surfaces make them hard to handle. Wighton’s solution was a pair of 3D printed holders over-molded with silicone that cradle the eggs like soft, elastic gloves. These carriers had to accept all sizes of eggs while providing enough grip to withstand the stresses of scoring and cracking. Early prototypes didn’t have enough strength to rip the egg’s inner membrane so Wighton added flexible tethers into the design. These tethers, embedded in the silicone, allowed for one-way stretch when inserting eggs but resisted twisting so the egg was secure. A vacuum seal, created by drawing air through hollow shafts, further secured the egg in place, a brilliant feature that made the grippers work for any egg, from small to jumbo.

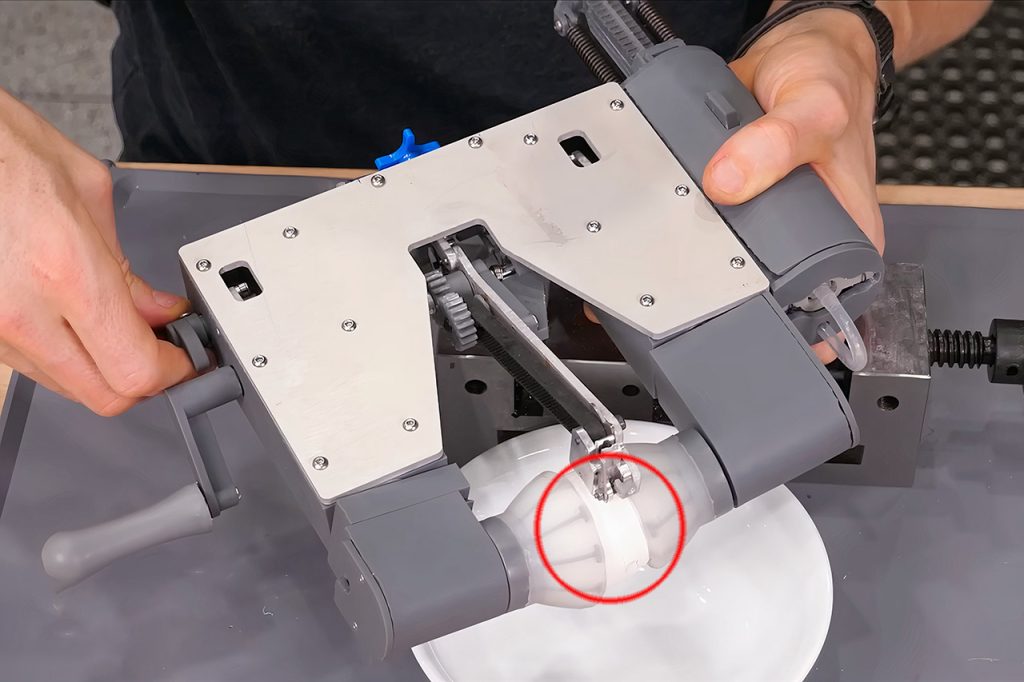

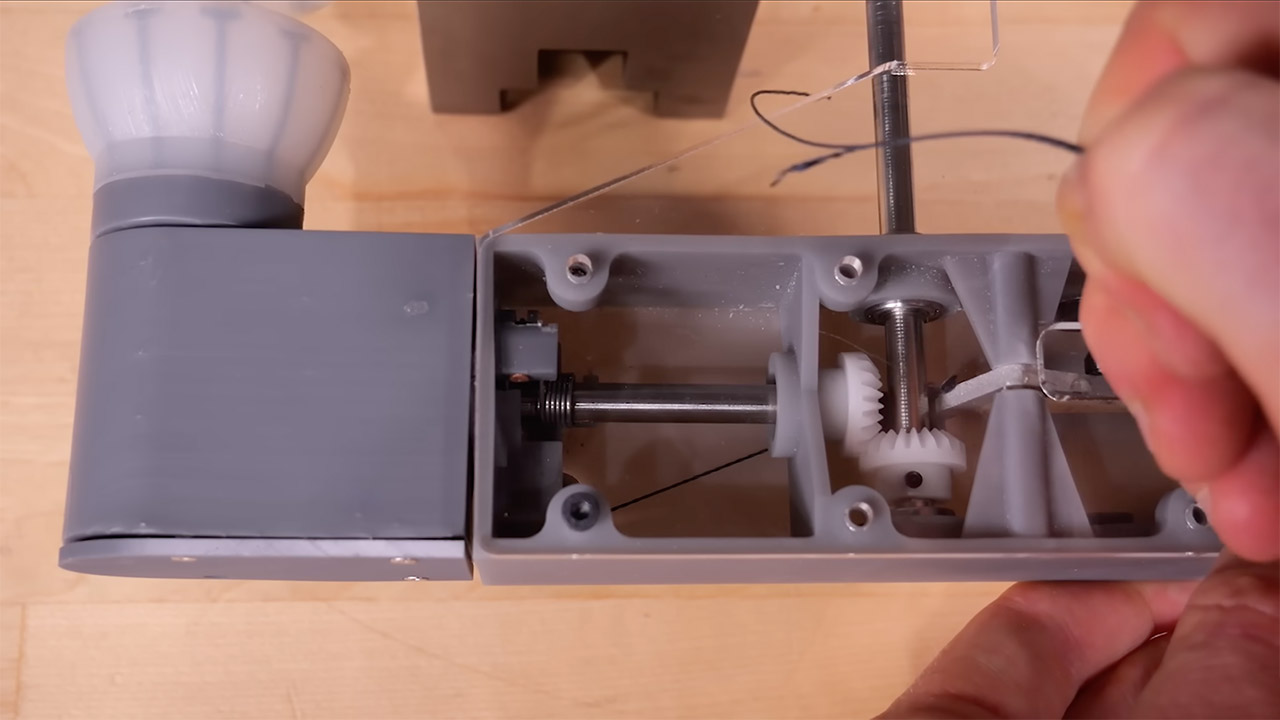

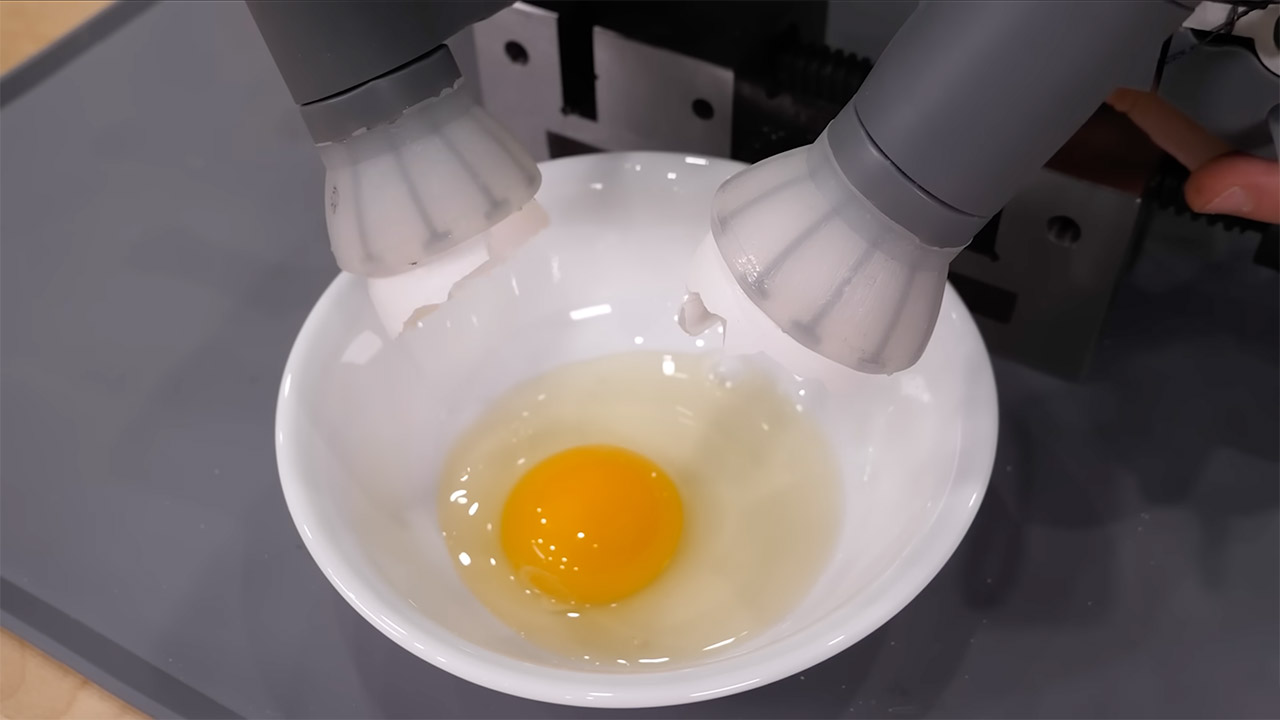

The main mechanism is a C-shaped frame that holds the egg holders which spin and slide to accommodate different egg sizes. The whole process is powered by a crank that rotates the egg via a set of drive shafts and bevel gears. An arm is attached to the frame with a scoring blade and a miniature hammer. The blade scores a line around the egg’s equator, weakening the shell, then the hammer taps gently to fracture it along the scored line. After cracking the grippers pivot down, tearing the membrane and releasing the egg’s contents into the bowl below. Finally an ejection system (originally spring loaded but later improved to use air pressure) pops the shells out, making the whole process hands free.

When it came to designing a single crank to orchestrate this sequence—score, hammer, dump, eject—that’s when things got wild. Wighton tried a mechanical “program” with a wheel to trigger each step in sequence, but eggs were unpredictable. Some needed more scoring than others, and the rigid pattern would often over-hammer and fracture the shells into random pieces. After much trial and error he abandoned the program wheel for a more flexible system: a knob to control scoring and cracking and a separate lever to control the cams that lift the cutting head and pivot the grippers. This allowed him to fine tune each step without using too much force.

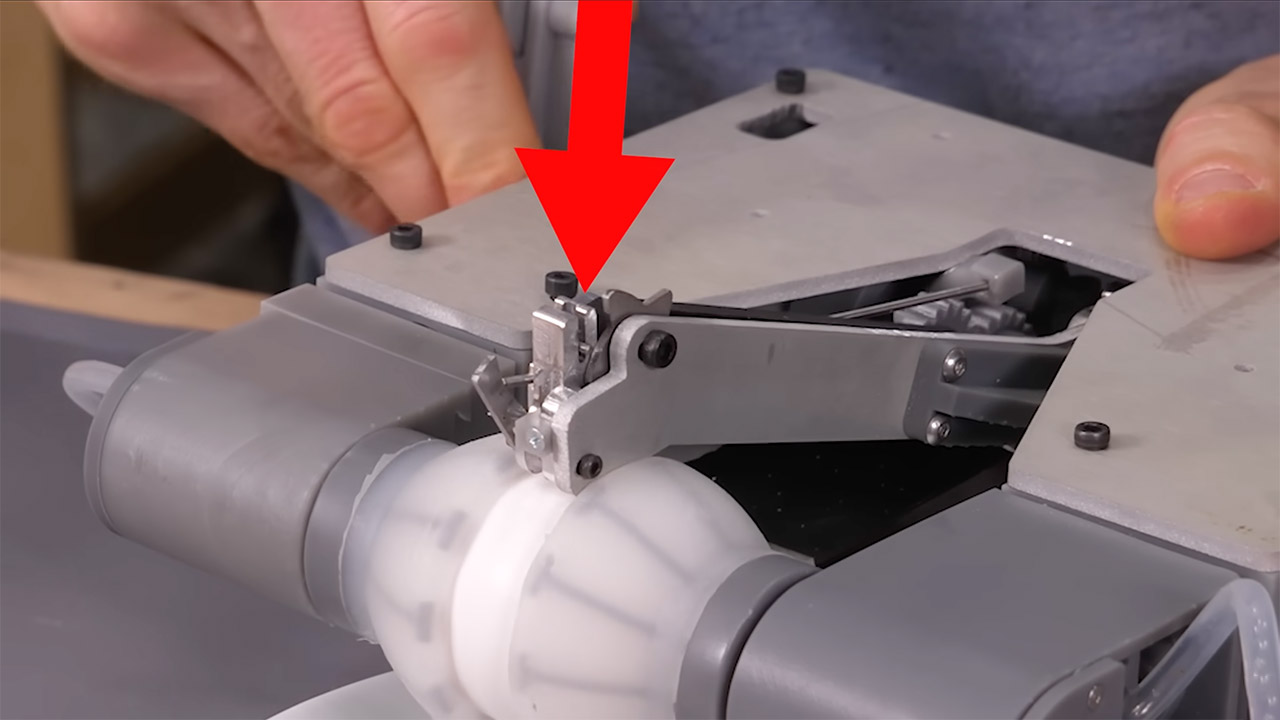

The cutting head itself is a work of art. This little piece, machined on a 5 axis mill, has a tiny blade and a spring loaded rod for hammering. Fitting these into a small space required a lot of design work with off axis holes and non-square surfaces that pushed Wighton’s equipment to the limit. Another challenge was the sharpness of the blade—too dull and it wouldn’t score, too sharp and it would tear chunks out of the shell. Wighton found the sweet spot after a few rounds and got clean, regular cracks that kept the egg’s contents intact.

Ejecting the shells was harder than he thought. The improved grippers were so powerful the original spring loaded ejectors couldn’t remove the shells. Wighton came up with an air powered ejection device that used the airtight grippers. By forcing air through the hollow shafts he could pop the shells out with force limited only by the air supply. A syringe like mechanism allowed him to vacuum the egg and then discharge it with air. But a problem arose if one shell ejected first it would release the air pressure and leave the other stuck. Wighton’s solution was a valve that closed one side and allowed a second push to open the remaining shell—a workable if not perfect solution for a prototype.

[Source]

Inventor Shane Wighton’s Egg-Cracking Machine Cracks the Code

#Inventor #Shane #Wightons #EggCracking #Machine #Cracks #Code