Inside Clone Robotics’ Ambitious Vision of Building Lifelike Musculoskeletal Androids

Dhanush Radhakrishnan, co-founder and CEO of Clone Robotics, sat down with Anastasi In Tech to talk about a sci-fi future we’re not quite ready for. His company’s mission? To build androids that move, act and function like humans—down to the muscle and bone.

Clone Robotics started with a childhood dream Radhakrishnan had after watching Boston Dynamics’ early demo videos. He imagined lifelike androids walking among us, a vision straight out of science fiction. Decades later, that future hasn’t arrived—yet. His frustration with the slow progress of humanoid robotics, combined with breakthroughs in deep learning, sparked the idea for Clone. He saw an opportunity to control complex, soft-bodied androids with high degrees of freedom, a problem he believes is now solvable. The company’s focus isn’t on incremental improvements but on building androids that can do anything a human can, from opening a heavy door to slicing a pineapple.

LEGO Disney & Pixar Wall-E & EVE Building Set for Adults, Ages 18+ – Home Office, Book Shelf, or Room…

- LEGO SET FOR ADULTS – The WALL-E and EVE (43279) building set offers adults 18 years old and up an immersive construction challenge featuring…

- 4 DISNEY PIXAR CHARACTERS – Builders can create iconic robots WALL-E, EVE, M-O and Hal from the hit movie—each with authentic functionality like…

- MINDFUL BUILDING EXPERIENCE – This detailed construction set lets builders practice advanced construction techniques for an immersive and relaxing…

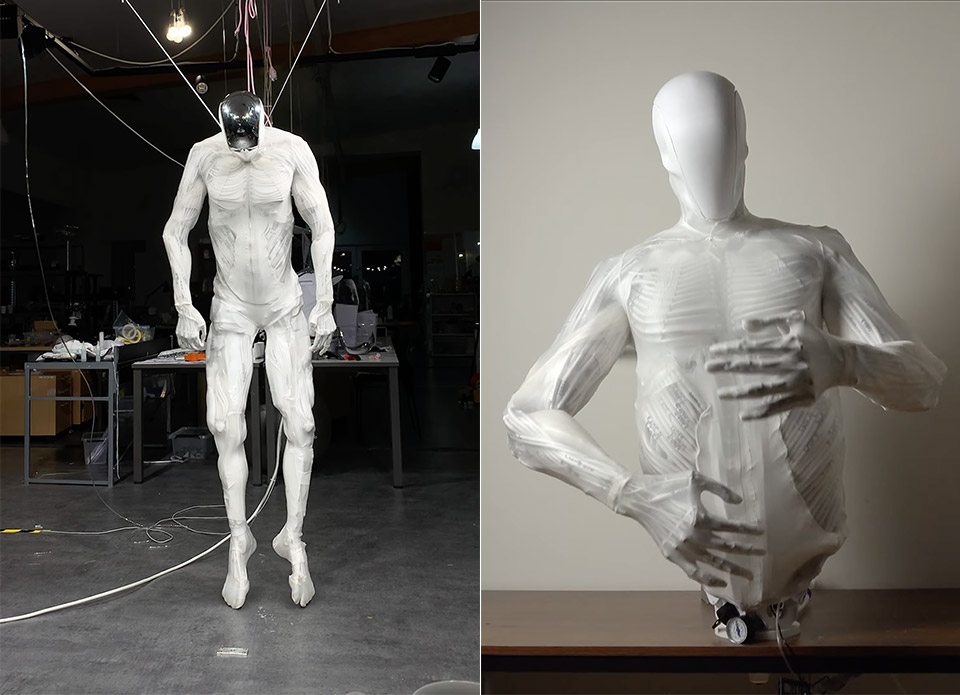

Why start with the hand? Radhakrishnan explained that the hand is the body’s most complex part, with more degrees of freedom than any other. It’s a maze of tendons, muscles and joints, where a single tendon can move multiple joints and multiple muscles can act on one. Clone tackled this first, building a durable, human-level robotic hand in 18 months—a feat Radhakrishnan is proud of. The hand’s complexity forced them to develop general design systems, like artificial ligaments and monolithic muscle-tendon structures, which they later scaled to the full body. This allowed them to go from a hand to a full-body prototype in about a year, a pace that shows they’re committed to keeping all tech in-house rather than using off-the-shelf components like industrial robotic arms.

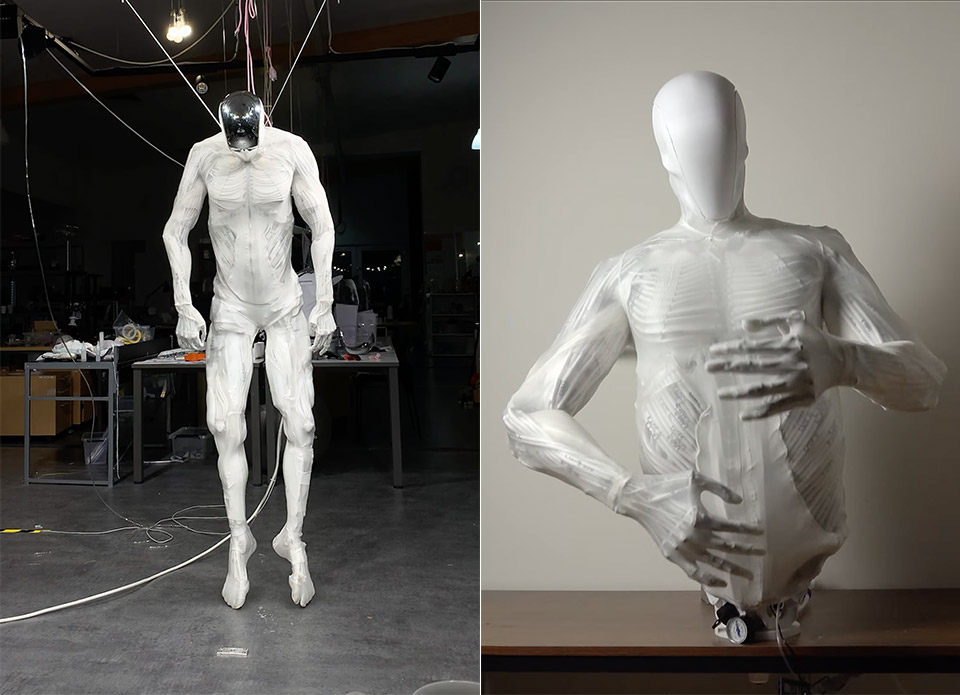

The core of Clone’s innovation is its artificial muscle technology. Unlike traditional motor-driven robots which require cramming as many motors and batteries as possible into a rigid frame, Clone’s androids use fluidic muscles (pressurized tubes that mimic human skeletal muscle). These muscles, based on the McKibben design, consist of an inner rubber tube wrapped in an inextensible textile sleeve. When filled with fluid (air for prototypes, water for final products), they contract linearly, pulling on artificial bones to create human-like movement. This simplifies design by allowing Clone to reference anatomy textbooks rather than engineering every joint from scratch.

Building a full body android isn’t just about mechanics. Stability, especially for bipedal walking, is a huge challenge. Radhakrishnan explained how most humanoid robots use physics simulators to train locomotion, generating virtual terrains like beaches or rocky paths to teach walking or running. Clone’s soft, muscle driven design makes this harder. Unlike rigid motor based robots which are easier to simulate as cylinders and links, Clone’s androids have dynamic, non linear components that require high fidelity simulation. Getting a “faithful clone of the Clone” in a simulator is their current bottleneck, but solving it will unlock untethered walking – a milestone Radhakrishnan says will “blow everyone’s minds”.

Powering these androids requires more than just muscles. Clone uses NVIDIA Jetson chips for the brain, one (or possibly two) for planning and motion control. Sensors are critical too: joint position, torque, muscle length and force are all measured to make the robot fully observable and easier to control. Tactile sensing, like a skin that can feel, is on hold for now as Clone focuses on position control. But Radhakrishnan hinted at future high resolution tactile skins that could generate force maps, enabling precise manipulation tasks. The hydraulic system, powered by a compact pump – or “hydraulic heart” – uses water to pressurize muscles, with a reservoir to manage fluid when muscles relax. Maintenance? Simple: the water stays in the system, but if it needs topping up the android could, in theory, “drink”.

Inside Clone Robotics’ Ambitious Vision of Building Lifelike Musculoskeletal Androids

#Clone #Robotics #Ambitious #Vision #Building #Lifelike #Musculoskeletal #Androids